The term medical device covers a wide range of applications from latex gloves to x-ray machines and biomedical devices such as heart valves. Traditional manufacturing processes including CNC machining and injection molding are commonly used for many existing medical devices such as prostheses, surgical instruments, and general instruments used by medical professionals.

The field of medical device manufacturing is rapidly growing, and due to the advantages offered by additive manufacturing, which include highly adjustable geometry, low cost, and the use of a wide variety of materials, these processes are well suited to meet the demand for Emerging medicine is suitable.

Processes used to manufacture polymer medical devices

Whether additive manufacturing or traditional manufacturing processes are the best solution for medical devices depends on several factors, including the overall application and application. Also, critical questions should be considered such as:

- Is this piece unique?

- Is the geometry of the part complex or customized for each patient?

- Is it a prototype, proof of concept, or finished product?

- What are the expected materials to use?

Answering these important questions will help determine the best choice for the project, whether it involves additive manufacturing, CNC machining, or injection molding.

In general, traditional manufacturing processes such as CNC machining or injection molding are better suited for higher volume tooling and parts due to higher start-up costs and longer lead times. Additive manufacturing is best suited for unique or low-volume parts, as well as prototypes or proof-of-concept designs.

Also, the geometry of the part and the properties of the required materials should also be considered. Injection molding and additive manufacturing are usually more beneficial for complex part geometries.

Common processes used in the manufacture of medical devices

1. CNC machining

CNC machines cover a wide range of cutting tools and machining processes and have applications suitable for all geometries and materials in medical device manufacturing.

CNC machining is suitable for medical equipment due to high start-up cost for finished products and higher volume.

2. Injection molding

Injection molding is more suitable for higher volume medical devices such as laboratory equipment housings.

A wide range of materials are available for injection molding, including higher strength and flexibility plastics including silicone plastics, sterilizable materials for dental and surgical instruments, and biomedical implants.

3. Fused Deposition Modeling (FDM)

This method is a low-cost solution for simple geometries and prototyping of repetitive and low-cost medical devices or plastic medical devices. where material strength is not a critical feature.

Also, the use of many plastic materials, including materials compatible with biomedical implants and some sterilizable surgical devices, are used.

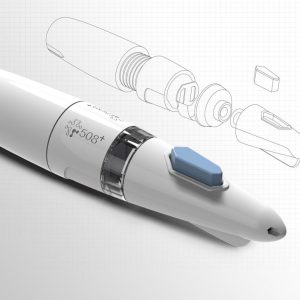

4. Stereolithography (SLA)

The best option for where a high level of detail and aesthetics is required. The parts have a smooth surface and can be painted.

In this method, the applications of medical devices include cheaper prototypes, surgical and dental instruments, and some biomedical implants.

5. Selective laser sintering (SLS)

In this method, the parts of polymer medical equipment have good strength and a high level of accuracy.

6. Metal printing

This method is best for complex designs and where material strength is a critical feature. Metal printing has the most applications for medical devices among all additive manufacturing processes due to its ability to print complex geometric shapes, higher material properties, and materials compatible with biomedical implants or sterilizable for surgical instruments.

Regulations related to the manufacture of medical equipment

There are eight main areas covered by FDA regulations:

⦁ registration

⦁ List of medical equipment

⦁ Pre-market notification

⦁ Pre-market approval

⦁ Exemption of research apparatus

⦁ Quality system regulations

⦁ Labeling

⦁ Medical device report

Applications for the manufacture of medical devices

The polymer medical equipment manufacturing industry is developing rapidly due to the advancement in manufacturing processes and continuous development in the field of medicine, especially biomedical engineering. Also, due to the wide range of products classified as medical devices, there is a wide variety of methods for manufacturing medical devices.

The field of medical device production is growing rapidly and the application of medical equipment production includes established products as well as modern technologies. Production of polymer medical devices includes device prototyping for modeling and validation, complex geometric medical devices, modeling for simulation and training for medical professionals and personal protective equipment.

2 Comments. Leave new

[…] سلامت و تضمین ماشین آلات پزشکی اطمینان حاصل شود. ایمنی دستگاه های پزشکی برای همه تولید کنندگان ماشین آلات پزشکی بسیار […]

[…] و بازرسی ثابت، قابل اعتماد و قابل تأیید است. تولید تجهیزات پزشکی تا سطوح میکرون و زیر میکرون میتواند با […]